Synthetic vs Oil-Based Grinding Coolant

Request a Quote

Which Should you Choose?

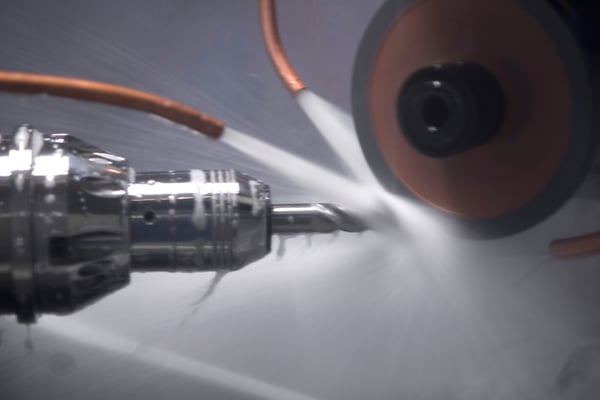

When Selecting a coolant for grinding, two of the most common options are synthetic and oil based coolants. Each performs differently, and the best choice depends on your grinding process and material.

Request a QuoteFeatures Table

Type

Synthetic Grinding Coolant

Cleaner operation with low foaming - More efficient cooling for precision grinding - works well with both hard and soft water

Less Lubrication than oil based coolant - May require close monitoring in very high pressure and temperature applications

Oil Based Grinding Coolant

Better lubrication for heavy-duty grinding - Stable flashpoint for high speed machining - Extends tool life in demanding operations

Can create more residue buildup - Higher maintenances and disposal needs - Odor can be stronger.

Benefits and use cases of Synthetic Grinding Coolant.

A synthetic coolant for grinding wheels delivers clean, low-foaming performance and can include additives to prevent cobalt leaching. It can work with both hard and soft water, making it ideal for precision parts in aerospace and medical applications.

Request a Quote

Benefits and use cases of Oil-Based Coolant

Oil-Based coolants provide good lubrication and a stable flashpoint for high-speed or heavy grinding operations. Oil based coolants provide extended tool life during demanding machining, making them suitable for automotive and large-scale production.