Centerless grinding is one of the machining processes that uses either a conventional or abrasive wheel to remove material from a workpiece.

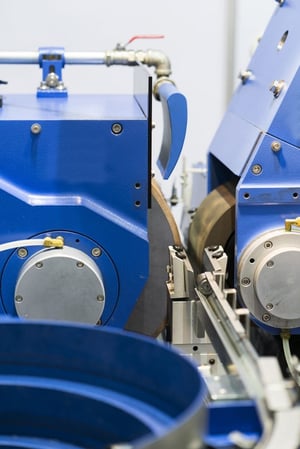

The grinding process involves the part being supported on the workpiece rest blade that sits between two rotating cylinders. Two wheels are involved in this process: a regulating wheel and a larger conventional or abrasive grinding wheel. The regulating wheel controls the rotational speed and hence the feed rate while the grinding wheel removes the material from the part. Because the workpiece is held in place by the pressure of the rotating wheel, no fixturing is required. Setup is easy and turnaround times are short. Rigid support also means no deflection during the grinding process.

Even with so many advantages and having been around for many years, centerless grinding has fewer practitioners than with other types of grinding. The lack of understanding of the fundamentals tends to be the biggest hurdle. That being said, we are going to break down the centerless grinding fundamentals below to (hopefully) improve your understanding.