CBN wheels offer several advantages for machining and grinding ferromagnetic magnets. They have exceptional thermal resistance, enabling them to withstand the heat generated during the manufacturing process. Additionally, CBN wheels exhibit high cutting efficiency and excellent longevity, making them suitable for high-volume production environments.

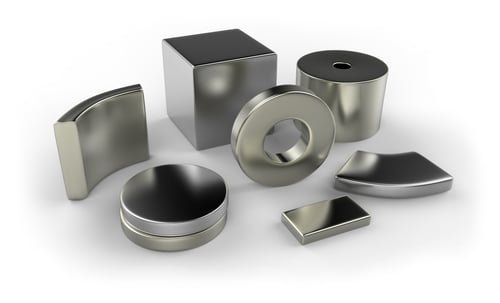

Diamond wheels are typically used for shaping NdFeB (neodymium-iron-boron) magnets. NdFeB magnets are known for their exceptional hardness and brittleness, requiring abrasive tools with high cutting efficiency. Diamond wheels, with their superior hardness and abrasive properties, are well-suited for shaping and grinding NdFeB magnets effectively.

Diamond wheels contain synthetic diamond particles bonded to the wheel’s surface using various bonding materials. The diamond particles provide the cutting action required to shape and remove material from the magnet. Due to the hardness of NdFeB magnets, diamond wheels can withstand the high forces and abrasion involved in the shaping process.

When using diamond wheels for shaping NdFeB magnets, it’s important to select the appropriate wheel specification based on the specific magnet dimensions, desired shape, and surface finish requirements. Factors such as wheel grit size, concentration, and bond type should be considered to achieve optimal cutting efficiency and desired results.

It’s worth noting that while diamond wheels are commonly used for shaping NdFeB magnets, the choice of wheel may also depend on other factors such as the size and complexity of the magnet, production volume, and the specific machining setup. Consulting with diamond wheel manufacturers or experts experienced in NdFeB magnet machining can provide further guidance on selecting the most suitable diamond wheel for your shaping needs.

However, it’s important to note that the specific choice of wheel may still depend on factors such as the magnet’s size, shape, and desired surface finish. It is always recommended to consult with a wheel manufacturer to determine the most appropriate wheel type and specifications for specific magnet manufacturing processes.