In the world of precision machining, thru-feed grinding is a form of centerless grinding and a standout process known for its efficiency and accuracy. It's the easiest way to create cylindrical parts with tight tolerances and a flawless finish. Let's dive into the basics and discover what makes thru-feed grinding a game-changer.

What is Thru-Feed Grinding?

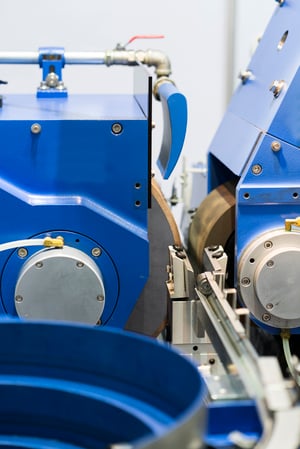

Thru-feed grinding is a special way of grinding where the workpiece keeps moving through the grinding wheels. It's different from in-feed grinding, where the workpiece is pushed into the grinding wheel. Thru-feed grinding works wonders for long, slender parts that need a consistent diameter and a smooth surface.

The setup involves a regulating wheel guiding the workpiece through the grinding zone. This continuous movement ensures a steady removal of material, making it perfect for large-scale production.

Precision: The Magic Touch

Thru-feed grinding is like a precision wizard. It maintains top-notch accuracy by smoothly feeding the workpiece through the grinding zone. This steady movement ensures even material removal, a crucial factor in industries where precision is non-negotiable, like aerospace and automotive manufacturing.

The regulating wheel is the unsung hero here, keeping the workpiece in check and preventing any wobbling. Combine this with CNC technology in advanced grinding machines, and you can program intricate grinding sequences for jaw-dropping accuracy at the micron level.

Efficiency on Steroids

Thru-feed grinding isn't just accurate; it's a speed demon too. The continuous flow of workpieces through the grinding process means less setup time and more material removed in less time. This efficiency turbocharges production cycles and saves costs, making it a go-to choice for manufacturers who want to work smarter.

This method is a champ when dealing with long, thin parts like pins or shafts. It ensures a consistent quality along the entire length, skipping the hiccups you might encounter with other methods.

Material-Friendly

Thru-feed grinding doesn't discriminate when it comes to materials. Whether you're dealing with tough steel, shiny stainless steel, or exotic alloys, this method can handle them all. Its adaptability makes it a valuable tool for various industries, from crafting delicate medical components to robust industrial parts.

In a Nutshell

Thru-feed grinding is the unsung hero of precision machining. Its ability to blend precision, efficiency, and versatility makes it a go-to for creating cylindrical components. As technology advances and demands for tighter tolerances grow, thru-feed grinding remains at the forefront, shaping the future of manufacturing. It's not just grinding; it's a symphony of precision and efficiency working together seamlessly.

What kind of grinding wheel do I need?

For the highest quality finished workpiece, Eagle Superabrasives Inc offers various centerless and regulating wheels. The abrasive material needed will depend on the workpiece that needs to be ground.

Check out our video on dressing grinding wheels by watching the following link.

Recent Posts

Subscribe to email updates

Subscribe to our blog to get the latest updates from the experts on Grinding Wheels! You can easily unsubscribe at any time