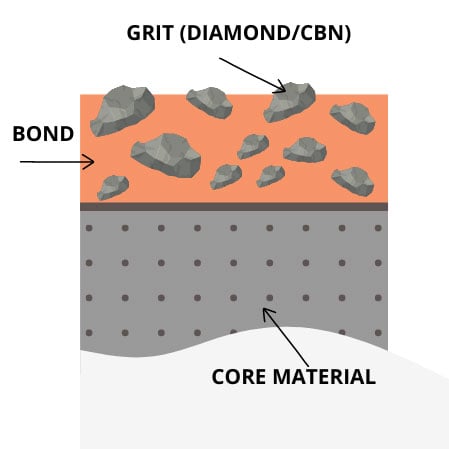

A grinding wheel is an abrasive cutting tool used in machinery operations across various industries to cut, slice, or refine extremely hard materials. Comprised of a bond and superabrasive, grinding wheels contain thousands of grain parts with multiple cutting edges to seamlessly shape a workpiece.

A grinding wheel with the proper bond, abrasive, and core material will sharpen itself on an ongoing basis. This process extends the life of the wheel, positively impacting the productivity and profitability of operational machinery.

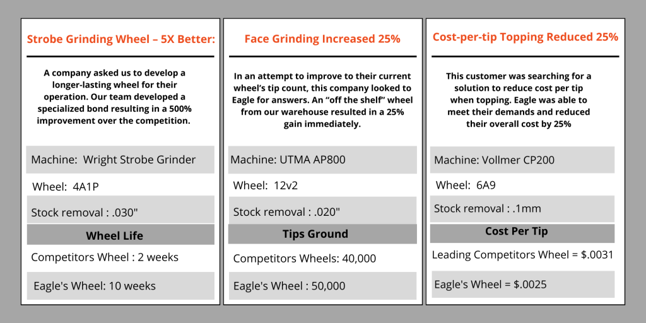

However, selecting the optimal grinding wheel for your application requires considerations that may impact the long-term success of your operations. Here’s what you need to know and consider as you search for a wheel for a specific project or when looking for a new vendor for your large-scale business.

![]()