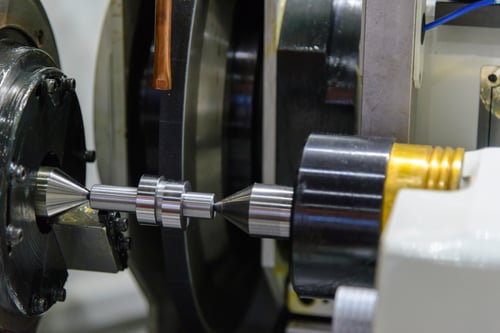

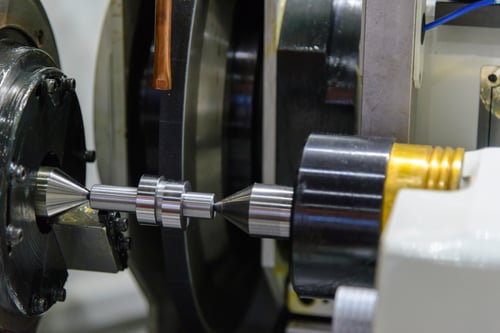

Vitrified bond diamond and cubic boron nitride (CBN) grinding wheels are the preferred choice when it comes to precision grinding. These wheels offer exceptional hardness, durability, and heat resistance, making them indispensable in various industries. To make the most of vitrified bond grinding wheels, it's crucial to understand their unique characteristics and follow best practices. In this article, we'll share nine expert tips to help you optimize your grinding process with vitrified bond wheels.

Optimize the Wheel Speed:

The first rule of thumb in precision grinding with vitrified bond wheels is to select the right wheel speed. Vitrified bonds can withstand high temperatures, but excessive speeds can lead to premature wear. Consult manufacturer recommendations for the ideal wheel speed for your application.

Understand Workpiece Material:

Different materials require different grinding wheel specifications. Familiarize yourself with the workpiece material's properties and choose the appropriate wheel accordingly. Vitrified bonds are suitable for a wide range of materials, including ferrous and non-ferrous metals, ceramics, and composites.

Tailor to the Application:

Consider the specific requirements of your grinding application. Whether it's achieving tight tolerances, fine surface finishes, or high stock removal rates, adjusting your vitrified bond wheel's specifications and operating parameters is crucial for success.

Proper Coolant Usage:

Vitrified bond wheels generate heat during grinding. Utilize the right coolant to dissipate heat effectively and prevent thermal damage to the workpiece. Oil-based or water-based coolants can be chosen based on your application needs.

Wheel Concentration Matters:

Vitrified bond wheels come with different concentrations of abrasive grit. Higher-concentration wheels are suited for applications requiring aggressive stock removal, while lower-concentration wheels are ideal for fine surface finishes. Choose wisely to meet your objectives.

Grit Size Selection:

Selecting the right grit size is essential for achieving the desired results. Smaller grit sizes provide finer finishes, while larger grit sizes excel at stock removal. Take into account your material, application, and desired finish to make the appropriate choice.

Dressing and Truing Techniques:

Regular dressing and truing of vitrified bond wheels are essential for maintaining their sharpness and shape. Understand the difference between dressing (reshaping the wheel's surface) and truing (aligning the wheel) and use the appropriate techniques.

Machine Maintenance:

Your grinding machine's condition directly impacts the performance of your vitrified bond wheels. Ensure that your machinery is well-maintained, including checking for vibration, alignment, and spindle runout.

Vitrified Bond Diamond vs. CBN:

Lastly, consider whether you should use vitrified bond diamond or CBN wheels for your application. Diamonds excel in grinding hard materials like carbide, while CBN is more suitable for ferrous materials. Make an informed choice based on your workpiece material and desired outcome.

Vitrified bond diamond and CBN grinding wheels are your go-to tools for precision grinding tasks. To unlock their full potential, adhere to these nine expert tips. By optimizing wheel speed, understanding workpiece materials, tailoring to your application, using proper coolant, selecting the right concentration and grit size, and practicing effective dressing, truing, and machine maintenance, you can ensure the longevity and high performance of your vitrified bond grinding wheels.

Remember, your choice of wheel can significantly impact the quality and efficiency of your grinding operations. So, put these tips into practice, and let vitrified bond diamond and CBN grinding wheels elevate your precision grinding to new heights. If you have any questions or need further guidance, our experts are here to assist you in achieving precision and excellence in your grinding processes.

![]()