Industries That Use High-Performance Diamond Grinding Wheels

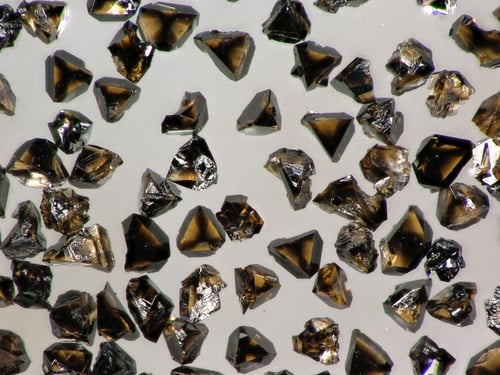

High-performance diamond grinding wheels are essential in modern manufacturing, where precision, durability, and high material removal rates are critical. These wheels are used across various industries to meet high tolerances, improve cycle times, and provide superior surface finishes. Here's an overview of industries that rely on diamond and CBN grinding wheels for high-performance grinding applications:

1. Automotive Industry

The automotive sector is a leading user of high-performance grinding wheels, particularly for manufacturing critical components such as crankshafts, gears, and cutting tools. Cylindrical grinding and surface grinding are common processes where precision is key, and high-speed, durable wheels are essential for maintaining quality. Diamond and CBN (Cubic Boron Nitride) wheels are frequently used due to their ability to grind carbide, hardened steel, and other alloys while offering excellent wheel life and material removal rates.

The demand for high-precision components, especially with the rise of electric vehicles, has pushed the automotive industry to seek more advanced grinding solutions. Centerless grinding and bond grinding wheels are also widely used to ensure accuracy and efficiency in the production of automotive parts across North America, Europe, and India.

2. Aerospace Industry

In aerospace, precision and tolerances are critical. Diamond grinding wheels are used to manufacture turbine blades, landing gear components, and high-strength alloys that are challenging to grind using conventional methods. Superabrasive materials like diamond and CBN ensure superior performance when working with substrates such as titanium and Inconel, which require high durability and precision.

The aerospace industry benefits from high-performance grinding wheels by achieving faster cycle times, better surface finishes, and optimized stock removal during CNC machining. Saint-Gobain and other manufacturers provide vitrified and resin bond grinding wheels to meet the unique needs of aerospace manufacturers across the USA, Europe, and India.

3. Tool and Cutter Manufacturing

For manufacturing cutting tools, especially those made from carbide or high-speed steel, diamond grinding wheels are indispensable. These wheels are essential for grinding and sharpening tools like drills, end mills, and saw blades, where high-precision edges and minimal stock removal are vital. Resinoid bond wheels and CBN wheels are often employed in this sector to handle tough grinding operations with minimal wear, maximizing wheel life and maintaining the sharpness of cutting tools.

This industry values high-performance grinding wheels for their ability to achieve a consistent surface finish, reduce cycle times, and improve the overall quality of cutting tools used in various machining operations.

4. Semiconductor and Electronics

In the semiconductor industry, diamond grinding wheels are widely used for precision grinding of silicon wafers and other delicate electronic components. High-quality grinding solutions are necessary to achieve the fine surface finish and exacting specifications required for semiconductors. Vitrified bond and resin bond wheels offer the precision needed for cutting and polishing these sensitive materials. The rise of 5G and advanced electronic devices further drives the demand for high-performance grinding tools.

5. Medical Devices

The medical device industry relies heavily on superabrasive wheels for grinding materials like stainless steel, ceramics, and specialized alloys used in surgical instruments, implants, and prosthetics. These grinding wheels provide the high precision needed for medical tools and equipment, ensuring minimal wear and high cutting performance.

6. Metalworking and Foundry

Diamond and CBN wheels are used in metalworking to grind hard alloys, coatings, and heat-resistant metals in industries like energy and heavy machinery. In foundry applications, high-speed grinding is essential for large-scale stock removal, often using superabrasive wheels to grind cast iron, steel, and other tough metals.

7. Construction and Stone Cutting

The construction industry uses diamond grinding wheels for cutting and polishing fiberglass, stone, concrete, and glass. These materials require abrasive grains like diamond for their durability and high removal rate during grinding operations. Tools such as diamond-tipped saw blades and cutting wheels help achieve precise cuts in hard construction materials.

Conclusion

High-performance diamond and CBN grinding wheels are integral to various industries, from automotive and aerospace to tool manufacturing and electronics. Their ability to deliver high durability, precision, and material removal makes them essential for manufacturers aiming to meet stringent tolerances and optimize production efficiency. As demand for high-quality components grows, these wheels continue to play a critical role in industries across North America, Europe, India, and beyond.

Recent Posts

Subscribe to email updates

Subscribe to our blog to get the latest updates from the experts on Grinding Wheels! You can easily unsubscribe at any time