Tips for Precision Grinding of Alnico Magnets with CBN Wheels

Precision grinding of Alnico magnets requires attention to detail and adherence to best practices. Here are some tips to achieve the best results:

- Use Coolant: Alnico magnets can heat up during grinding, potentially affecting their magnetic properties. Using a suitable coolant is essential to dissipate heat and prevent thermal damage to the magnets. Ensure that the chosen coolant is compatible with the CBN wheel and the magnet material.

- Control Speed and Feed Rates: Optimal speed and feed rates are crucial for maintaining precision and achieving the desired surface finish. Adjust these parameters based on the specifics of the grinding task and the recommendations provided by the CBN wheel manufacturer.

- Operator Expertise: Skilled operators with experience in magnet machining play a vital role in achieving precision. Their knowledge and expertise in setting up and operating the grinding equipment can make a significant difference in the quality of the finished product. Ongoing training and skill development are valuable investments in ensuring consistent, high-quality results.

- Monitor and Maintain Equipment: Regularly inspect and maintain grinding equipment to ensure it operates optimally. This includes checking for wheel wear, proper alignment, and coolant flow. Any equipment issues can impact the quality and precision of the grinding process.

Preventing Demagnetization During Grinding

Demagnetization is a potential risk during the grinding process, as exposure to heat and external magnetic fields can affect the magnetic properties of Alnico magnets. To mitigate this risk:

- Choose the Right Wheel Material: Ensure that the CBN wheel used is compatible with Alnico magnets and does not generate excessive heat during grinding. CBN wheels are a preferred choice due to their heat resistance and precision.

- Control Heat: Proper control of heat generation during grinding is essential. This includes using appropriate coolant, adjusting grinding parameters, and ensuring that the grinding process does not raise the magnet's temperature to levels that can lead to demagnetization.

- Protect from External Magnetic Fields: Keep magnets away from external magnetic fields that could influence their magnetism during grinding. Minimize exposure to strong external magnetic sources to maintain the integrity of the magnets.

- Temperature Control: Depending on the specific Alico magnet material being processed, it may be beneficial to monitor the temperature of the magnets during grinding. This can be achieved using temperature sensors or infrared thermography to ensure that the magnets remain within their safe operating temperature range.

- Post-Grind Inspection: After the grinding process is complete, it's essential to conduct a thorough inspection of the Alnico magnets. This inspection should include checking for any signs of demagnetization or damage to the magnet's surface. Any issues should be addressed promptly to maintain the magnet's performance.

Benefits of Precision Grinding with CBN Wheels

Precision grinding with CBN wheels offers numerous advantages, aligning with the keywords and the overall theme of this article. Let's explore these benefits in more detail:

- Enhanced Magnetism: Precision grinding with CBN wheels ensures that Alnico magnets maintain their magnetic strength. This is crucial for applications where consistent and strong magnetic fields are required.

- Surface Finish: CBN wheels produce smoother and more consistent surface finishes, which are essential in many applications. A smooth surface not only enhances the magnet's appearance but also improves its functionality and interaction with other components.

- Longevity: By minimizing the risk of pullout and demagnetization, precision grinding with CBN wheels contributes to the long-term durability of Alnico magnets. This durability is particularly important in applications where magnets are subjected to wear and environmental factors.

- Tight Tolerances: Achieving tight tolerances is often a requirement in precision machining. CBN wheels are capable of maintaining these tight tolerances, ensuring that the final product meets the necessary specifications.

Applications of Alnico Magnets in Industry

Alnico magnets, with their impressive magnetic properties and high-temperature resistance, find applications in various industries. Here are some key areas where Alnico magnets are commonly used:

- Electronics: Alnico magnets are utilized in sensors, relays, and magnetic switches in the electronics industry due to their stability and reliability in different temperature environments.

- Automotive: They are employed in automotive systems, including ignition systems, fuel injectors, and various sensors, where their resistance to high temperatures and strong magnetic fields is essential.

- Healthcare: Alnico magnets are used in medical devices, such as MRI machines and magnetic resonance spectrometers, where the need for a strong magnetic field is paramount.

- Aerospace: In aerospace applications, Alnico magnets are found in sensors, actuators, and navigation systems that require magnetic stability and performance in challenging environments.

- Musical Instruments: Alnico magnets are often used in the pickups of electric guitars and other musical instruments to produce a unique and clear magnetic response, contributing to the instrument's overall tone.

- Manufacturing: They play a role in various manufacturing processes, including magnetic chuck applications for holding workpieces during machining.

- Energy Production: Alnico magnets are used in generators and turbines in the energy sector, where their high-temperature resistance ensures reliable performance.

- Research and Development: They are indispensable in laboratories and research facilities where strong and stable magnetic fields are needed for experiments and analyses.

Exploring Alnico Magnet Alloys

Alnico magnets come in different compositions, with Alnico 5 being one of the most well-known. Each composition offers unique magnetic properties suitable for specific applications. Let's briefly explore some common Alnico magnet alloys:

- Alnico 5: This alloy is known for its strong magnetic field and is commonly used in various applications, including guitar pickups and sensors.

- Samarium Cobalt Magnets: Although not strictly Alnico magnets, SmCo magnets share some characteristics with Alnico. They offer exceptional resistance to high temperatures and corrosion, making them suitable for demanding applications.

- Cast Alnico Magnets: These magnets are produced using a casting process and can be customized to achieve specific shapes and sizes. Cast Alnico magnets are highly versatile and find use in diverse industries.

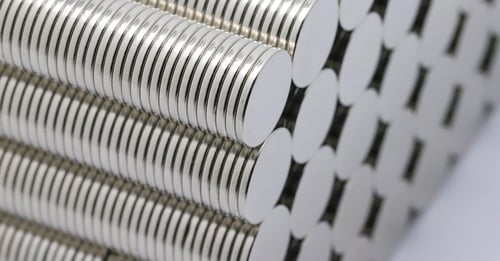

Alnico magnets are just one of the types of magnets that can be ground with CBN wheels. Other kinds of magnets that can be ground by CBN include neodymium magnets, bar magnets, ferrite magnets, and ceramic magnets.

![]()

Precision grinding with CBN wheels not only preserves the magnetic properties of Alnico magnets but also opens up a world of possibilities for their application in a wide range of industries. So, when precision matters, make sure to choose CBN for your Alnico magnet grinding needs.

In conclusion, Alnico magnets continue to be at the forefront of magnetic technology, powering innovations in numerous industries. Their ability to withstand high temperatures and maintain strong magnetic fields makes them indispensable in applications where stability and reliability are paramount. By employing precision grinding techniques with CBN wheels, manufacturers can ensure that Alnico magnets meet the stringent requirements of modern technology and industry.

Eagle Superabrasives is here to provide the expertise and products you need to ensure success in your magnet grinding endeavors. When precision and performance are non-negotiable, trust in the power of CBN wheels to unlock the full potential of Alnico magnets.

By embracing the art of precision grinding and harnessing the capabilities of CBN wheels, industries can continue to rely on Alnico magnets as a cornerstone of their technological advancements and innovations.