MUST HAVES

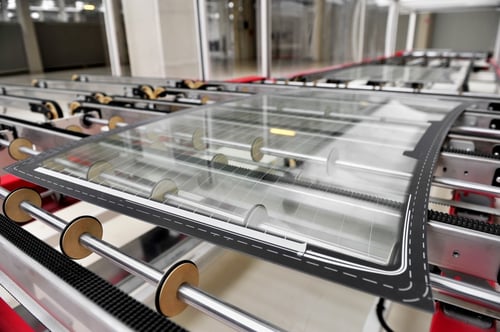

Wheels must cut freely with minimal chipping yet maintain shape. Edges of glass are inspected several times during a production run to ensure any chipping is within allowed tolerances. The shape of a glass grinding wheel is crucial as it ensures uninterrupted production by minimizing the need for wheel changes.n. Typically sets of wheels are ready to be placed on a machine immediately, but unanticipated retooling should always be the exception. In most full-production beveling operations, wheels are used for a specific amount of hours regardless of the amount of life left on the wheel. This way the wheel change is anticipated and can be done as efficiently as possible.

OTHER IMPORTANT CONSIDERATIONS

When purchasing a glass grinding wheel, consistency, performance, customization options, and dimensional accuracy are key. Eagle also offers a Make and Hold program so that you will always have a wheel in stock, as well as direct engineer support.

IS IT HARD TO CHOOSE THE RIGHT WHEEL?

With Eagle, it does not have to be. Glass grinding is not any more difficult to choose a wheel for than any other industry we manufacture wheels for. Our engineers will analyze your needs and performance goals and manufacture a wheel to achieve those goals.

COMMON PURCHASING MISTAKES

Remember that pricing isn’t everything. Eagle’s wheels are not always the cheapest on the market- and for good reason. Using an “off the shelf” wheel when something more custom would fit your application can cause time and loss of profit down the road. We calculate the cost per part produced with your current wheel and make a direct comparison to our wheel so that we can prove our wheel is more efficient.

WHAT IF I BUY THE WRONG WHEEL?

Having the wrong wheel may cause machine downtime, falling short of production goals and inferior or scrapped parts. The wrong wheel also causes a constant need for wheel re-dressing, therefore more of the wheel is wasted during re-profiling.