Diamond Wheels vs. CBN Grinding Wheels: A Comparison

Selecting the right abrasive is critical in precision grinding, and one of the most common choices engineers face is diamond vs CBN grinding wheels. Research in Nature shows that the wear rate of diamond during turning on mild steel can be 10⁴ times greater than on brass of similar hardness, due to catalytic graphitization at elevated temperatures. This explains why CBN wheels are the standard for hardened steels, while diamond remains unmatched for carbide, glass, and ceramics.

Understanding these differences helps manufacturers improve tool life, control heat, and achieve more consistent finishes across materials.

Understanding the Basics: What are Diamond and CBN Grinding Wheels?

Diamond grinding wheels and CBN grinding wheels are used in various manufacturing processes. They are commonly used in industries such as automotive, aerospace, and tool manufacturing.

Diamond grinding wheels use synthetic diamonds grits, which are extremely hard and durable. They have excellent cutting ability and are capable of working on hard materials such as carbide, glass, and ceramics.

On the other hand, CBN grinding wheels contain cubic boron nitride grits, which is a synthetic material that is second only to diamond in terms of hardness. CBN wheels are particularly effective in grinding ferrous materials, such as hardened steels and cast iron.

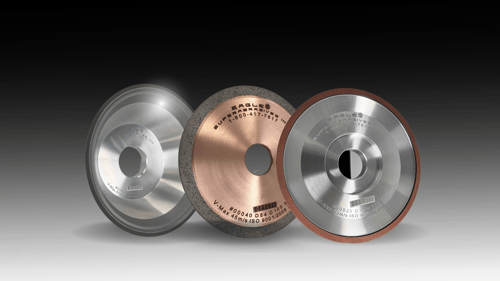

Both diamond abrasive tools and CBN abrasive tools are available in a variety of shapes and sizes to suit different abrasive applications. They can be used for precision cutting, surface finishing, and cylindrical shaping, among other processes.

Material Properties: Diamond Wheels Explained

Diamond wheels are known for their exceptional hardness and wear resistance. They are capable of maintaining their shape and cutting ability even under high temperatures and heavy loads. This makes them suitable for working on hard materials that would quickly wear out other types of abrasive wheels.

Diamond wheels have high thermal conductivity, which helps dissipate heat generated during material removal. This reduces the risk of thermal damage to the workpiece and prolongs the life of the wheel.

Another advantage of diamond abrasive tools is their ability to produce a high-quality surface finish. They can achieve fine finishes and sharp edges, making them ideal for applications that require precision cutting or shaping.

However, diamond abrasive tools are not suitable for ferrous materials, as the carbon in the diamond reacts with iron (in steel) at high temperatures, causing the diamond to degrade rapidly. For working on ferrous materials, CBN abrasive tools are the preferred choice.

Material Properties: CBN Grinding Wheels Uncovered

CBN abrasive tools are highly regarded for their exceptional hardness and thermal stability. They are capable of working on hard materials at high speeds without losing their cutting ability.

Unlike diamond, CBN does not react with iron at high temperatures, allowing the tool to maintain its sharpness and longevity.

In addition to their excellent cutting performance, CBN abrasive tools also offer good thermal conductivity. This helps dissipate heat generated during material removal, preventing thermal damage to the workpiece.

CBN abrasive tools are particularly suitable for working on hardened steels, cast iron, and other ferrous materials. They are commonly used in applications that require high material removal rates and precision grinding. For more information on CBN grinding wheels look at this Ultimate Guide to CBN grinding wheels.

If you’re curious where CBN comes from, here’s the short version and why its chemistry matters.

How Is CBN Abrasive Made and What Sets It Apart Chemically?

CBN is engineered to be very hard and very stable on ferrous materials.

- How it’s made: Manufacturers start with boron nitride and convert it into a “cubic” crystal under very high pressure and temperature. That crystal form is what gives CBN its hardness.

- What makes it different: CBN contains boron and nitrogen, not carbon. Because there’s no carbon, it doesn’t react with iron at grinding temperatures.

- Why that helps in practice: The grain keeps its edge on hardened steels, so the wheel stays sharp longer, holds size, and produces a steady finish with less risk of burning.

Comparative Analysis: Performance in Various Applications

When it comes to performance, superabrasive cutting tools and CBN cutting tools each have their own strengths and weaknesses.

Superabrasive cutting tools excel in working on hard and brittle materials, such as carbide, glass, and ceramics. They offer superior cutting ability and produce fine surface finishes. However, they are not suitable for ferrous materials.

On the other hand, CBN cutting tools are highly effective for ferrous materials, such as hardened steels and cast iron. They have excellent thermal stability and maintain their cutting ability even at high speeds. However, they are not as effective on hard and brittle materials.

The choice between superabrasive cutting tools and CBN cutting tools depends on the specific material and the desired outcome. It is important to consider factors such as material hardness, operational speed, and surface finish requirements when selecting the appropriate tool.

Making the Right Choice: Factors to Consider When Selecting a Grinding Wheel

Selecting the right wheel is crucial for achieving optimal results. Here are some factors to consider when choosing between diamond wheels and CBN cutting tools:

- Material being ground or cut: Diamond wheels are ideal for hard and brittle materials as long as they don’t contain iron, while CBN cutting tools are better suited for most ferrous materials.

- Operational speed: The cutting speed of the wheel depends on the material being cut, the application and the machine.

- Surface finish requirements: Both diamond wheels and CBN wheels can provide excellent surface finishes as long as they are being used on the appropriate material.

- Cost considerations: CBN Wheels are generally more expensive than Diamond wheels. However the material being ground must be taken into account when choosing between the wheels.

By considering these factors and understanding the specific requirements of the application, manufacturers can make an informed decision when selecting between diamond and CBN cutting tools.

Partner With Eagle Superabrasives to Choose the Right Wheel

Eagle Superabrasives helps teams pick the right superabrasive (diamond or CBN), bond system (resin, vitrified, metal, hybrid), and dressing/coolant strategy—so your wheel performs as expected.

Contact our applications team today to review your materials and duty cycles and lock in a wheel spec that improves capability and reduces unplanned downtime.

Recent Posts

Subscribe to email updates

Subscribe to our blog to get the latest updates from the experts on Grinding Wheels! You can easily unsubscribe at any time