Copper Tungsten Erosion Wheels: Revolutionizing Grinding Processes

The world of manufacturing and machining has been continually evolving, with advanced materials and innovative processes leading the way. Among these developments, Copper Tungsten (WCu) alloys and Copper Erosion Wheels have emerged as pivotal elements, especially in Electrical Discharge Machining (EDM), spark erosion, and other high-precision applications. In this article, we delve into the significant roles played by these edm electrodes, focusing on their use in various machines and the benefits they bring to the industry.

Understanding Copper Tungsten and Its Applications

Tungsten Copper alloy, known for its unique combination of tungsten and copper, offer an exceptional blend of properties. With high wear resistance, excellent thermal conductivity, and superior electrical conductivity, these alloys are ideal for electrodes in EDM processes. The WCu electrodes are particularly significant in machining hard materials like carbide, PCD (Polycrystalline Diamond), PCBN, and refractory metals.

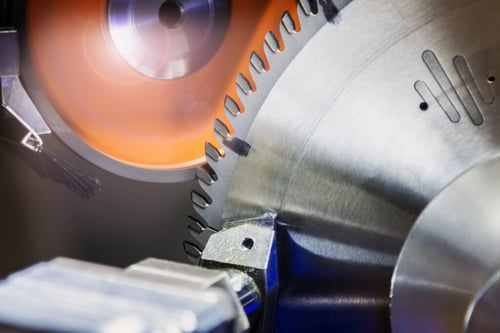

Copper Tungsten Erosion Wheels: Revolutionizing Precision in Grinding Machines

Copper Tungsten Erosion Wheels, comprising blends like 80/20, 70/30, and 75/25 WCu, are pivotal in the advancement of precision grinding. These wheels, utilized in various grinding machines, have transformed the machining process, offering unparalleled accuracy and efficiency. Let's explore the key grinding machines that employ these revolutionary wheels.

Vollmer QXD 250, Vollmer 260, and Vollmer QF/QR 270 QM eco Disc Erosion Machines

Vollmer's range, including the QXD 250, 260, and QF/QR 270 QM eco, represents the pinnacle of disc erosion technology. These machines are designed for the high-precision sharpening of PCD (Polycrystalline Diamond) tools. The incorporation of Copper Tungsten Erosion Grinding Wheels in these machines allows for exceptional erosion performance, thanks to the optimal blend of tungsten and copper. The high melting point and excellent thermal conductivity of these wheels ensure a longer lifespan and consistent performance, essential for maintaining the intricate geometries of PCD tools.

Jeffer EM400

The Jeffer EM400 stands out in the realm of tool and cutter grinding. This machine, when equipped with Copper Tungsten electrodes, enhances its capabilities in sharpening carbide and PCD tools. The wheels' resistance to high temperatures and wear, coupled with their superior electrical conductivity, makes them ideal for the precision grinding demands of the EM400.

SparQ and SparQ-Pro

The SparQ and SparQ-Pro machines, known for their efficiency in tool grinding, benefit significantly from the use of Copper Tungsten Erosion Wheels. These wheels' resistance to arc ablation and oxidation, along with their low gas content, ensure a smooth and precise grinding process. The uniform microstructure of the wheels contributes to their durability and cost-effectiveness, making them a preferred choice for these high-performance machines.

Walter Helitronic Raptor and Diamond Evolution

Walter's Helitronic Raptor and Diamond Evolution are renowned for their precision in tool grinding. The integration of Copper Tungsten Erosion Wheels in these machines allows for superior surface finishes and precise cutting edges. The wheels' high electrical conductivity and excellent heat dissipation function make them ideal for the high-speed operations of the Walter machines, ensuring efficient and accurate grinding of complex tool geometries.

Copper Erosion Wheels: A Game-Changer in Tool Sharpening

Copper Erosion Wheels have revolutionized the way saw blades, PCD tools, and carbide tools are sharpened and maintained. Machines like Vollmer QXD 250, Vollmer 260, and Walter Helitronic Raptor rely on these wheels for precision and efficiency.

Benefits of Copper Erosion Wheels

- Improved Surface Finish: These wheels provide a superior surface finish, crucial for tools that demand high precision and clean cuts.

- Increased Durability: The combination of copper and tungsten in these wheels offers high resistance to wear and corrosion, translating into longer life and consistent performance.

- Versatility: Suitable for various materials, including tungsten carbide and PCD tools, these wheels are versatile for different machining tasks.

![]()

In conclusion, the amalgamation of copper tungsten in electrodes and the application of Copper Erosion Wheels in machining and EDM processes symbolize significant strides in material science and manufacturing technologies. As industries continue to demand higher precision and efficiency, these components are poised to play a critical role in shaping the future of manufacturing.

Recent Posts

Subscribe to email updates

Subscribe to our blog to get the latest updates from the experts on Grinding Wheels! You can easily unsubscribe at any time