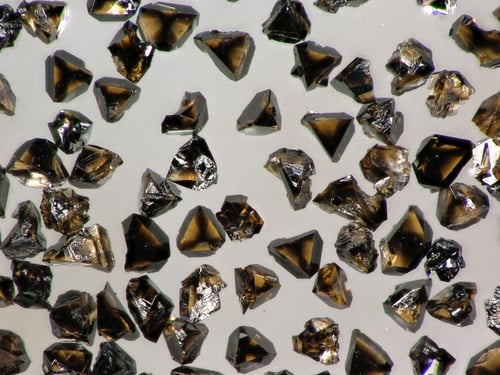

Benefits of CBN Grinding Wheels

1: Superior Durability and Long Lifespan

CBN grinding wheels stand out for their exceptional durability. The hardness of cubic boron nitride means these wheels can withstand intense grinding processes, often outlasting conventional abrasive wheels. This longevity is particularly beneficial in high-volume manufacturing environments where frequent wheel changes can lead to significant downtime. The extended lifespan of CBN wheels translates into cost savings and increased productivity, as less time is spent on truing and reshaping the wheels.

2: Efficient and Precise Grinding

Precision grinding is a hallmark of CBN wheels. Their ability to maintain a sharp edge allows for consistent, accurate grinding, making them indispensable in industries where precision is crucial, such as aerospace and automotive manufacturing. The precision of CBN wheels is not just about achieving the right dimensions; it's also about maintaining tight tolerances and achieving a superior surface finish on the workpiece. This high level of precision ensures that components meet stringent specification requirements, a must in high-tech industries.

3: Reduced Heat and Thermal Damage

One of the significant advantages of using CBN wheels is their high thermal conductivity, which helps dissipate heat more efficiently during the grinding process. This feature is particularly important when working with materials that are sensitive to heat, as it reduces the risk of thermal damage. Less heat generation means that coolants can be used more effectively, or in some cases, grinding can be performed dry without adversely affecting the workpiece or the wheel's performance.

4: Lower Overall Cost and Downtime

Although the initial cost of CBN grinding wheels may be higher than conventional wheels, their longer life and durability offer a lower total cost of ownership over time. Fewer wheel replacements mean less downtime for wheel changes and maintenance, leading to uninterrupted production cycles. This efficiency is crucial in reducing the cost per part, which is a critical factor in competitive manufacturing markets. Moreover, the consistent performance of CBN wheels means that less time is spent adjusting machines to compensate for wheel wear, further enhancing productivity.

5: Versatility in Grinding Applications

CBN wheels are not limited to a narrow range of applications. Their versatility extends to various grinding processes, including surface grinding, cylindrical grinding, centerless grinding, and honing. They are equally effective in grinding different materials, from hardened steels to aerospace alloys, providing manufacturers with a single solution for multiple grinding needs. This adaptability makes CBN wheels an invaluable asset in diverse manufacturing environments, from high-precision toolmaking to large-scale automotive production.

![]()

CBN grinding wheels represent a significant advancement in grinding technology, offering benefits that traditional abrasive wheels cannot match. Their durability, precision, thermal stability, cost-effectiveness, and versatility make them a superior choice in modern manufacturing processes. Whether it's reshaping cutting tools, achieving fine finishes on aerospace components, or efficiently processing hardened steel, CBN wheels deliver performance and quality that enhance the capabilities of any grinding operation.

As the industry continues to evolve towards more demanding materials and tighter specifications, the role of CBN grinding wheels becomes increasingly vital. By embracing this superabrasive technology, manufacturers can achieve higher efficiency, better quality, and more cost-effective production processes.